To begin, my 'bench' is really a table that sits in the middle of a room full of junk. Literally, in the middle of a room full of junk. Junk to the left, junk to the right. Junk straight ahead and behind. There's even junk piled at my feet. Electronics gear, fishing gear, radios, camping gear, you name it.

The bench started out years ago as a table that I did all my fly tying work on. Yes, I used to tie a LOT of flies for fly fishing, so many that I'm still using flies I tied up over 5 years ago! As my interest in electronics grew I started plopping more and more test and builder gear on the table until one day I decided I needed a dedicated electronics work bench. I packed up all my fly tying gear and put it in storage. I fully intend to get back to fly tying one day (it is a very relaxing and artistic way to spend a few hours), but for now it's all about pushing electrons around.

Like most electronics hobbyists the collection of stuff grew slowly as my needs evolved. Nothing on this bench is 'lab grade'; most of it is good quality hobbyist gear that came out of China or the far east. Regardless, it all fits the bill nicely. So let's have a look:

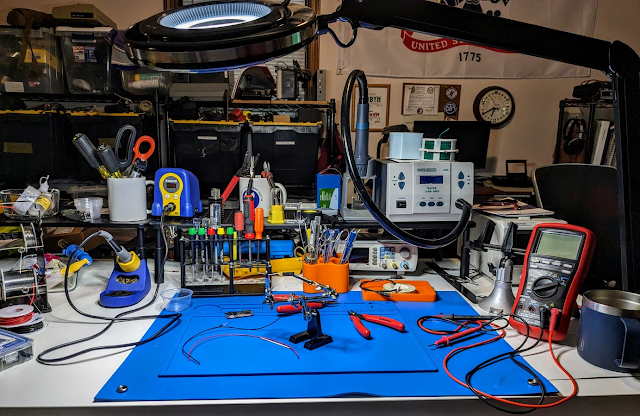

Let's start with lighting, since that is probably one of the biggest issue I face in this cave. I depend highly on the LED magnifier lamp on the swing arm you see in the picture. It's absolutely essential for focusing light on the work area and magnifying the project. It's the true unsung hero of the workbench. It wasn't cheap, but it was a solid investment. I use it every single day.

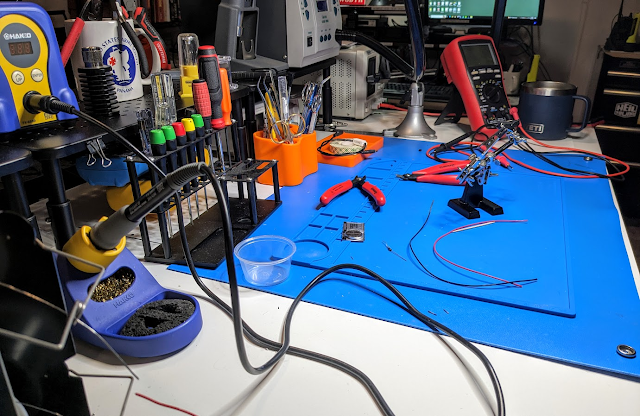

Next, the soldering station. It's a Hakko FX888 digital station, and it is the single tool on the bench that has allowed me to tackle so many projects. In the past I used various single wattage/single heat irons that were clumsy performers. This soldering station, with it's digitally controlled temperature settings and interchangeable tips has allowed me to tackle projects that I just couldn't in the past. Again not cheap (but not too expensive either), but well worth the money.

Multimeter. I've got a small collection of multimeters - a few Fluke's (to include an 87V), a few Brymens, some off-brands. The one that has become my standard bench meter is the Brymen 869s. I bought this meter on the recommendation of several reviewers, particularly David Jones, author of the EEVblog website and YouTube channel, and Joe Smith, who does destructive testing of multimeters. Both heaped high praise on this meter for its features and accuracy. While not as physically rugged as a Fluke, it carries a UL and German TuV certification, so it more than meets it's electrical overload protection ratings. Plus it offers far more features than the highly vaunted Fluke 87, at about half the price, and the display is far easier to read. Because Brymen does not sell its meters in the US (they have a marketing agreement with Greenlee) I had to order this one from a distributor in Poland, of all places. This is another tool that gets used almost every day.

Hiding away behind the Brymen multimeter is a Siglent bench power supply. While most of my power testing requires 12 - 14 volts, something easily supplied by one of my ham radio switching power supplies, I occasionally have to take things down to 9 or 5 volts. Hanging off to the side is a collection of test leads I can connect to the power supply, allowing me to hook up to just about anything.

The Quick 8610 hot air rework station sitting on the shelf is a recent acquisition. I needed it to do some SMD component replacements on an amplifier project, and it works like a champ. I've used it on several other projects since, and I'll be using it on the upcoming IC-7300 battery replacement (Icom solders the OEM battery directly to the board, making it hard to get off with a conventional soldering iron). Honestly, it can be frightening how fast it works. While this is not a top-end unit, it gets very good reviews from folks who do board-level repairs on computers and other electronics. Louis Rossmann, who runs a business doing Apple board-level work and has a very active YouTube channel, actually prefers this rework station to the much more expensive Hakko systems he previously used.

The blue mats are a combination of an electrostatic grounding mat and a silicone soldering mat. When working on sensitive electronics I'll use a grounded wrist strap that snaps to the mat and connects to the house ground. Very cheap insurance.

In the middle of the blue mats sits one of those inexpensive hobbyist 'third hand' tools that I have to admit is all but indispensable. Yes, I've got much more expensive electronic component holders, including a rotating circuit board work holder that can support a full-sized computer board, but this cheap little tool gets used the most for simple tasks like soldering two pieces of wire together. You'll also see a small PanaVise head sitting off to the right. That gets used a good bit, too.

Hand tools. I've got a large assortment of hand tools - screw drivers, cutters, wire strippers, pliers, scissors, tweezers, small rulers, X-acto knifes and more. Honestly, I don't know where a lot of this stuff came from. Some I used in my fly tying activities, some I just had laying around when I started this hobby. The two hand tools that get use most on the bench are sitting right up front - the red handled side cutter and the miniature pliers. I go through a set of these about once a year, particularly the side cutters. When they get dull don't even think about trying to sharpen them. Just toss 'em and get another set.

Magnifiers. I have to admit it, my eyes are not what they used to be. When I joined the Army in 1979 I had 15/15 vision. Today I can't even get out of bed without glasses. I'm almost 67 and have a bit of cataract forming in both eyes. I need both good light and magnification. I've got a number of small hand-held magnifiers that live on my bench, plus I've got an OptiVisor headband magnifier with an LED light attachment, something I find I'm using more and more.

I do have an oscilloscope - a Siglent digital model, but I've had little use for it over the past year so it's sitting in storage on a shelf in the far back.

Last, but certainly not least, are all the consumable supplies sitting on or near the bench -

- denatured alcohol for cleaning just about everything electronic

- Q-tips

- spools of solder, paste flux and liquid flux, along with solder wick and a surprisingly effective spring loaded 'solder sucker'

- electrical tape

- double sided tape

- heat resistant tape (really needed when doing hot air re-work stuff)

- small zip ties

- a box of toothpicks

- a tube of silicone glue

- a bottle of superglue

- paper towels

- glass cleaner

- a roll of twist-tie material

- Sharpie markers

- small parts containers - little plastic salsa 'bowls' that I steal from local Mexican restaurant chain whenever we go there for lunch or dinner

- pens & pencils, and a notebook

- Yeti coffee cup full of my favorite coffee 😄

And wire. Lots and lots of wire. When working on the bench most of my wire needs fall into the 18 - 22 gauge arena. Lately I've been going through a good bit of 22 gauge Teflon coated wire. I keep two spools of red and black on-hand.

I think that's about it. If you have any questions about anything you see just drop a comment below.

W8BYH out